Release Notes V2.10 - V2.50

Release Notes TransLution Version 2.10 – Release Date 13 August 2007

Release Summary

There were two main areas of focus for this release - the first was to move the data stored in the TransLution.xml file to be stored in the database and the second was to do real-time process of scanner based picks and transfers.

Data Management Enhancements

Global Settings Stored in the Database

Many of the global settings such as Syspro logon information, Picking setup options, data processing options etc were previously stored in a file called TransLution.xml. The issue was that the settings in the file could at times be lost when changing database logon details. These settings are now saved in the database. As a result of this, there are quite a few changes to different set up forms all of which is covered in the detailed technical release notes and forms part of the 2.10 user manual.

Real Time Processing

Previously TransLution processed all scanner job when the job was finished. This means that only when the job was finished were all the stock movements done - this applies to both manual and auto processing. In V2.10 however, there is an option of doing real time processing. This means that when doing a transfer for example, as soon as the source location, product and quantity have been scanned, the stock is moved out of the source location even though TransLution does not yet know where the stock will be moved. The stock is moved into a virtual location for that scanner job and once the target location is scanned, all the stock in the job is moved to the appropriate target leaving the job stock location empty. There is a mechanism to manage non-empty job stock locations for jobs that have been cancelled or could not be properly completed.

Cycle Counting

One of the main benefits of real time processing is that because stock is moved as it is scanned, the warehouse stock picture is a lot more accurate than it would have been before and it is this increased level of accuracy that will make it possible to do proper cycle counts. TransLution 2.10 does have the beginnings of cycle count functionality in place. It is possible to create cycle counts and scan them in much the same way as a standard stock take. The cycle count is automatically processed and the scanned data is stored along with the variance to the expected count. Initially it will be necessary to address the variances by

doing a discrete stock adjustment or, if required, a stock take. A future release will allow the variances to be corrected from the scanner directly at the bin.

Additional Enhancements and Error Corrections

There have been a number of smaller enhancements added to the 2.10 build. These are described below:

Default Target Location

The scanner prompt sequence has been modified to allow for the definition of a default prompt. Currently this only works on the target prompt but it does mean that for certain scanner prompt sequences it is not required to scan a target location. In the current release this does not work on any other prompts.

Enhancements to Sales order error correction form

Previously this form did not show all sales order that were in a status of 15. In particular, sales orders that were in error due to for example communication failure did not appear. This form now shows all sales orders with a TransLution transaction header status of 15.

Improved Error Handling on Syspro Updates

Previously, if a SORTBO call to put a line onto backorder in Syspro failed, there was no error reported in TransLution and the transaction header status did not go to 15 (error). This is now changed and if a SORTBO call fails, the TransLution transaction header status goes to 15 and the sales order status in Syspro is rolled back from 8 to 4. The SORTBO calls that succeeded are not rolled back but this does not affect the end result because when TransLution reposts the transaction, each line is first put onto back order and then the shipped quantities are released from back order.

Inter Location Transfer Correction

Currently, when a specific Inter Location Transfer line fails where the Source and Target Location belong to different Warehouses and the Stock Transfer header table has already been marked as Completed for an Inter Warehouse Transfer this line will never be processed. To correct this problem, the Inter Location Transfer Correction process does not only attempt to complete the Stock Transfer, but it also checks to see if an Inter Warehouse Transfer is needed. If so, a Warehouse Transfer Document action and one Warehouse Transfer Transaction are created with this line. If there is already an unprocessed document open, then the Transfer line is added as a new Transaction on the Transfer Document. This way all Transfer Error corrections can be processed across Warehouses if required.

Release Notes TransLution Version 2.21 – Release Date 30 November 2007

Release Summary

This was a significant release and some of the major changes were the ability to do dynamic substitution, bulk imports of products and locations and bulk imports of discrete stock adjustments. There were also various enhancements added to carrier functionality.

Processing Enhancements

Dynamic Substitution

The driver behind the implementation of dynamic substitution is when sites have the same item stored and packed in multiple pack sizes or pack configurations. If we imagine a scenario of a soft drink stored in a warehouse in 3 pack size configurations - units, 6 packs and crates of 24. If a 6 pack was scanned into a location, then TransLution managed this as a 6 pack. It was this that gave us the ability to be able to tell users how many 6 packs, crates and units to pick to get to 100 cokes. The down side of this though is that if TransLution knows about a 6 pack in a location and the user wants to move a single can of coke then one of two scenarios arose. The first is that location - product validation was enabled and the scan would not be permitted. The second scenario is that the validation was not enabled and then the scan would be permitted and the location would end up still containing a 6 pack but now being 1 unit or can negative. The total would still be 5 cokes but of course a negative product in the location is not correct. Dynamic substitution is how this is avoided.

Effectively if Substitution is enabled, TransLution will store everything in units and even if a pack barcode is scanned, TransLution will dynamically convert that into the unit barcode and process it as if a unit barcode was scanned. This has another benefit for most users. When dynamic substitution is enabled, users will be required to scan the barcode of the product they are dealing with (any pack size) but enter the number of units or eaches they are moving. This is a crucial point - dynamic substitution deals in unit quantities only. Many scanner users struggle greatly with the concept of specifying the number of packs or boxes they are moving rather than the number of units so when substitution is enabled, the entire system deals in units only. This effectively make TransLution a lot easier to use.

Bulk Imports of Products and Locations

With this release, TransLution supports the ability to import both products and locations into the relevant TransLution tables from a CSV file. The real benefit of this is that by simply creating one row in a file, all the product, product type, pack, pack type and ERP commodity data is automatically created.

Discrete Stock Adjustment Imports

There is also an application that runs that will read data in a database table and create the corresponding discrete stock adjustments in TransLution.

Improved Handling of Sales Orders

Previously TransLution supported the ability to cancel sales orders from the single sales order viewing form. This caused problems when orders were inadvertently cancelled. This functionality has been enhanced by changing the feature to one that removes the order from processing (puts it into a status 25). There is another form where all orders in status 25 can be viewed and from there either cancelled or returned to processing. Both removing the order from processing and canceling the order now have a warning message displayed. In addition, when trying to cancel an order, the order status in Syspro is queried. If the order is cancelled in Syspro it may be cancelled in TransLution else it may not be cancelled.

An additional enhancement is that both and the start of the checking process and at the end of the checking process, the sales order is validated in Syspro. If the sales order has changed in Syspro the user is alerted and TransLution will not allow the order to be updated to a status of 8 which could allow the incorrect invoice to be generated.

Carrier to Carrier Transfers

A new type of stock transfer has been created. Carrier to Carrier allows a user to transfer product directly from one carrier to another carrier.

Suggestion Prompts

TransLution has for a while now supported the validation scripting functionality which effectively allows a selected stored procedure to run after a barcode has been scanned to do additional, custom validation. The suggestion prompt however runs before the barcode is scanned and allows the user also to run a stored procedure. The result of this stored procedure is however not returned as an error, it is returned as part of the scanner display and is intended to provide information or suggestions of what to scan to the operator.

Form Based Enhancements

Multi Pick Slip Creation Form

Significant changes were made to the multi pick slip processing form to improve the use for users creating pick slips in environments with many sales orders. A range of filters were added to allow users more control over which sales orders are visible to them - it is possible to filter by order type, document status and TransLution Status. Additional users can select to add in filters for customer name and order number. Finally, it is possible to view the lines on a sales order from this form without the need to change to the single sales order viewing form. This means the most users will not need to access the single sales order viewing form any longer.

Discrete Stock Adjustment Form

This form was modified to improve performance. Filters on item selection were added that work in the same way as filters for locations. This means that if there are 10 000 items, the form opening is not slowed down.

Job Manager

This form has been modified to add the same concept of four custom buttons as most other processing forms in TransLution. Also, the grid on the form shows additional detail - both the function area name are shown and the relevant ID for the job type. For example, if the job is picking, the pick slip ID is shown and if the job is a stock take, the stock take session ID is shown.

Stock Take Templates

It is now possible to define stock take templates which allows lists of items or locations to be built that will be scanned in a specific stock take session. This allows the templates to be set up once but used repeatedly, saving time and effort. The same concept applies to cycle counts as well.

Additional Enhancements and Error Corrections

There have been a number of smaller enhancements added to the 2.21 build. These are described below:

Multiple Instances of the TransLution Client (PC and Scanner)

In this release it is possible to prevent two instances of the TransLution client from running. This applies to both the PC client and the RF Scanner client.

Inter Warehouse Transfer Enhancement

Previously if a move carrier transfer was done between two locations mapped to two different Syspro warehouses the contents of the carrier were not part of a Syspro inter warehouse transfer. This has now been changed.

Saving Comment Lines on Orders

TransLution supported the option to download comment lines on sales orders. These were downloaded if the option was selected but the comment lines were not saved. They are now saved in the database as transaction lines.

Changes to Syspro Logons

Previously every user in TransLution had a Syspro username and password defined. In this release, there are four Syspro users required by TransLution, one for each functional area.

Correcting Errors with Real Time Processing

There were a number of areas identified where errors had to be corrected with real time processing - pack and unpack carrier did not work in real time processing and the auto unpack carrier option did not work either.

Release Notes TransLution Version 2.30 – Release Date 16 May 2008

Release Summary

This was a fairly small release with only a few key enhancements, the main one being the addition of a sequential pick slip number to TransLution.

Processing Enhancements

Sequential Pick Slip Numbering

Previously the Pick Slip ID has been used as the Pick Slip number in TransLution. However, due to the way that pick slips are created, it may be that the ID's are not sequential. This leads to gaps in the pick slip numbering making it hard for users to know with certainty if all pick slips have been printed and picked. Adding a sequential pick slip number makes this management significantly easier for users.

Pre and Post Checking Validation

This functionality was release in Version 2.21 but it was not configurable. In Version 2.30 it has been made configurable. It has also been linked to the option to update Syspro post checking. If no validation is done, the no updates will be done to Syspro.

Discrete Stock Adjustment Imports

This is also an enhancement to a Version 2.21 feature. The discrete stock adjustment function has been modified to run as a service.

Form Based Enhancements

Job Manager

This form has had two changes made to it. Firstly, the form did not display jobs that belonged to the non-processed function area type. This has been changed. Also, the form has been changed so that if a user is logged on as an administrator then they can cancel scanner jobs otherwise they can only reallocate the jobs.

Sales Order Forms

TransLution will only download sales orders using the bulk order retrieval function - either the floating button form or the sales order retrieval service. This means that all buttons allowing sales orders to be downloaded have been removed from the single sales order viewing form and the multi pick slip creation form. the only button that remains is the button that will re-fetch the order lines.

Additional Enhancements and Error Corrections

There have been a number of smaller enhancements added to the 2.30 build. These are described below:

ERP Service Changes

All errors are now logged as errors and not as events to make problem solving easier.

Business Object Event Changes

There is now a flag in TransLution that allows users to select to ignore warnings from the business object or not.

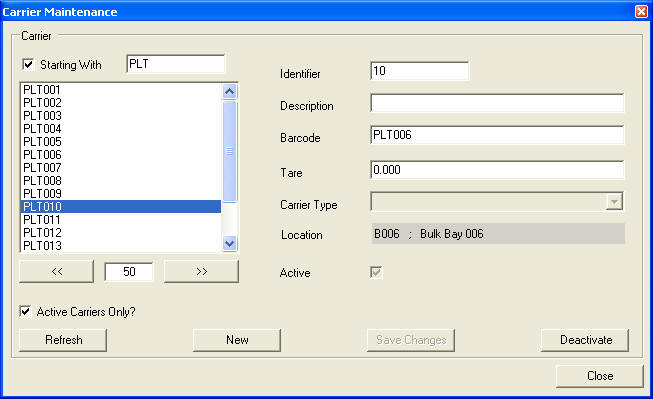

Carrier Enhancements

There is a form allowing carrier types to be defined. There is also a new form to allow for carriers to be defined and for a tare to be associated with each carrier.

Inter Warehouse Transfers

Multiple scanned transfers are no longer grouped together into a single inter warehouse transfer. The single biggest benefit of this is that it is now possible to record the Syspro journal number against a specific Warehouse Transfer Transaction which is in turn linked to a specific stock transfer line. There will be additional enhancements to inter warehouse transfers in future.

Release Notes TransLution Version 2.35 – Release Date 18 August 2008

Release Summary

There were three main areas of user focus for enhancements in this release. The first was a significant improvement in the pick slip creation process and the second was creating carrier types that can only contain a single product. The final enhancement was part of our ingoing process of improving the stock take functionality in the product.

Processing Enhancements

Stock Take

In 2.35 it is now possible to create either first or second count jobs from the Stock Take processing form and also to create a scanner based Supervisor Override.

Single Product Carriers

It was clear that when TransLution carriers were used in a bulk environment, the carriers often had only one product in them. By allowing a carrier to be defined as a single product carrier, when scanning to unpack a carrier, it will not be required to scan the product. Similarly, when packing a single product carrier, it will not be possible to pack a second product into the carrier.

Carriers as Documents

TransLution has always supported the ability to create a carrier when packing products into it. It has never been possible to create a carrier when unpacking it because it was an unknown carrier and it would end up with a negative stock position. This new concept allows the user to unpack a new carrier but rather than creating a negative config position for it, there will only be stock movements shown in the database.

Form Based Enhancements

Pick Slip Creation

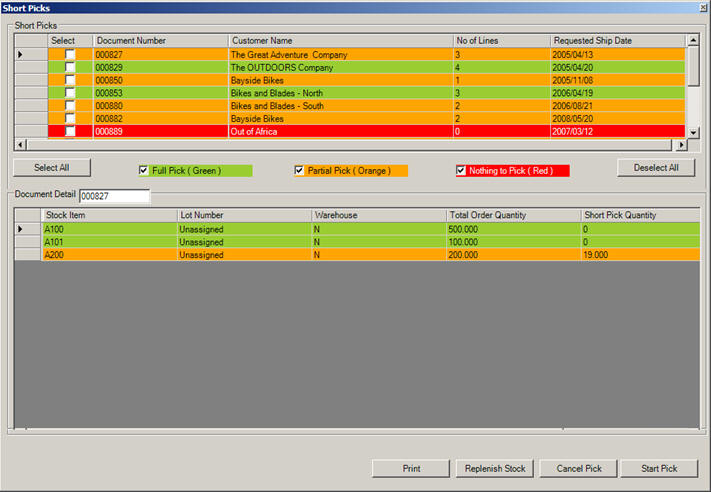

The Short Pick form as displayed from the Multi Pick Slip creator has been significantly enhanced. The original form showed the lines of the Sales Orders that were to be placed on the Pick Slip with some able to be fully picked, others partially picked and some with nothing to pick.

The new form shows the selected Sales Orders in a grid with the Sales Order Lines which belong to that Sales Order in a second Grid as follows:

The main benefit to be gained with this enhancement is the ability to create pick slips more quickly. It is now very easy for users to identify which orders do not have any short picks and with 3 or 4 mouse clicks create pick slips for all of these orders before then only starting to spend time looking at short picks.

Additional Enhancements and Error Corrections

There have been a number of smaller enhancements added to the 2.35 build. These are described below:

Menu Items

There have been new menu items added to 2.35 for some of the more commonly used warehousing functions.

Bulk Import Performance

The bulk import service has been significantly tuned to improve the performance

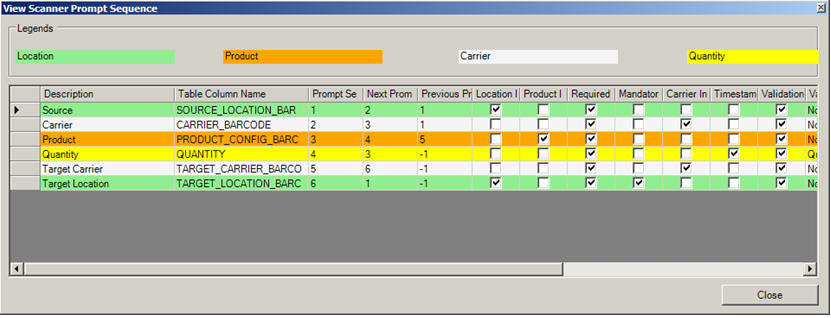

Scanner Prompt Sequence Viewing

There is a new form that shows the form allowing the user to see all the prompts for a given function area in a single grid.

Release Notes TransLution Version 2.40 – Release Date 23 January 2009

Release Summary

There were a number of key enhancements in this release. We added the ability to pass stock adjustments to Syspro on a selective basis per adjustment (based on user rights). In previous versions of TransLution the option to pass adjustments to Syspro or not was a global setting. We also significantly improved the processing of inter-warehouse transfers particularly as they relate to moving products in carriers. Finally, there were various improvements made to the scanning software.

Processing Enhancements

Discrete Stock Adjustments

In 2.40 it is possible for users with the appropriate access rights to modify the selection to post Discrete Stock Adjustments to Syspro or not. This can be done both from the adjustment form or via the Discrete Stock Adjustment service. An additional enhancement is that a ledger can now be passed to Syspro as well with each adjustment posted.

Move Carriers/ inter-warehouse Transfers

There were situations in 2.35 and earlier versions where when carriers were moved between two Syspro warehouses and then immediately unpacked, the inter-warehouse transfer to Syspro did not include all the correct stock. This has now been corrected and whenever a carrier is moved, the stock that is in the carrier at the time of the move is what forms part of the transfer to Syspro. The audit trail around the inter-warehouse transfer has also be improved and Syspro journal numbers are recorded for each transaction. Finally, we have added the option to select whether to consolidate transfers of the same product between the same warehouses or not.

Scanning Enhancements

A number of scanner based changes have been made. Scanners can now be configured to be allowed to drop into batch mode or not when the RF network is lost. This is very important when significant custom validation is being done because the scanner can't do this validation while in batch mode. The batch configuration option of validation of scanned barcode length has been added for carrier barcodes. The last scanned barcode display has been made longer to allow barcode lengths in excess of 30 characters to be displayed. Also, scanning validation around carrier barcodes has been improved to prevent scanning barcodes that have the right fixed portion but variable portions of the incorrect length.

Form Based Enhancements

2.40 did not have many form changes but there were one or two minor enhancements.

Carrier Maintenance

The carrier maintenance form has been improved by the addition of filters to improve the usability of the form. In addition, the location where the carrier currently can be found is also now displayed on the form. This gives an easy way of finding a carrier in a given implementation.

Location Mapping

The same filters have been added to the function area location mapping and the ERP location mapping form to improve performance when there are a large number of locations.

Reason Maintenance

The reason code maintenance form has a new filed where a ledger code can be entered. If an adjustment is done in TransLution using a specific reason code, the ledger code specified (if there is one) will be passed to Syspro.

Additional Enhancements and Error Corrections

There have been a number of smaller enhancements added to the 2.40 build. These are described below:

Refresh Buttons

On the scanner prompt sequence maintenance form, the single Refresh button used to refresh both the list of function areas and the list of scanner prompts. There is now one refresh button for each area.

Audit Trail

The audit trail data in the TransLution has been significantly improved to ensure that when reporting transaction history, all the right data is easily available.

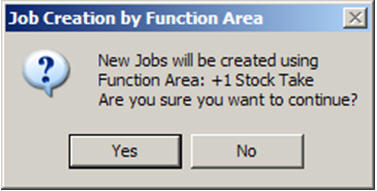

Stock Take

One of the most common errors with Stock Take was creating the sessions using the wrong function area or creating additional jobs using the wrong function area. In 2.40, when a new stock take session is created or a new scanner job is created from the stock take processing form, the user will be presented with a form telling them what kind of session/job has been selected. This just gives the user a reminder and an opportunity to correct their mistake.

Another common error is that the same location was counted multiple times in different sessions and then when the stock take was processed, the counts in one session were written off. This has been prevented by not allowing the same location to belong to more than one active session at a time. These two fairly small changes should have a large impact in terms of preventing the most common stock take errors.

Release Notes TransLution Version 2.50 – Release Date 23 November 2011

Release Summary

There were some significant new features added to the latest version of TransLution. The two main new features were the TransLution Touch Screen functionality and the new Direct Scanner to ERP communications functions.

There are also various smaller enhancements to existing functionality such as using single business objects calls for multiple inventory or WIP transactions in order to reduce the number of Syspro journals generated in high volume environments, changes to the waybill logic and enhanced scanner functions. These will all be described in more detail below.

TransLution for Touch Screen

While TransLution Touch Screen is based in large part on the TransLution PC scanner functionality it offers some significant enhancements. The first main change is that there are four configurable VB script buttons and 2 configurable banners on the form. The top banner is intended to alert the operator to issues and can be configured to change colour and to contain a custom text message depending on the current situation. The second banner is intended to convey information only and can show variable text but not change colour. The 4 VB Script buttons can be configured to use either the job number if there is an active job or just to perform any task regardless of the job number.

The scanner prompts work like they do for the PC scanner once a job has been selected but there is additional functionality here too. Once a scan has been completed there is the option to call up an additional overlay form before moving on to the next prompt. This overlay can have anything up to 8 buttons configured and each button can be clicked to execute either a VB Script or a stored procedure or both. The system can then be configured to close the overlay automatically when any of the buttons has been clicked.

Finally, there is also the option to run a VB script when a job is completed which is a useful way to print a label or perform some other function as the user ends the scanning for a job.

Direct Scanner to Syspro Functionality

This is the functionality that has made the release of the TransLution EazyScan product possible. Fortunately, the power of this new functionality is available to all existing TransLution users too. Simply put, the new functionality allows almost any transaction posting business object to be called directly from the scanner where the scanned values in the scanner job are mapped directly to the business object variables that are required by Syspro. This feature works on function areas that are not processed and perform no real function in TransLution as well as on standard TransLution function areas such as product transfers.

The benefit for users of simple system with no complex barcodes or lots or carriers is that they can use the scanner to communicate directly with Syspro with no need for locations barcodes or stock codes to be maintained in TransLution.

Enhancements to Existing TransLution Functionality

PC Scanner Enhancements

A VB Script can be run after every successful scan if required. This can be used for example when a job label is scanned to print the finished product label.

Automatic Waybill Closure

A waybill can be closed automatically after pick slips have been printed so that no new pick slips can be added to that waybill

Single Business Object Calls

When doing, for example, inter warehouse transfer posts to Syspro, TransLution groups all posts for the same stock code between the same warehouses into a single call. We were however doing separate calls for different sotck codes and warehouses. In high volume environments, this was found to generate too many journal numbers in Syspro until there were no journal numbers left. In order to prevent this, a single business object post is now made for all transfers or job receipts or job issues at the time when the service is called.

None of this grouping of course applies to the direct Syspro communications described above. In that case, as soon as the last prompt is scanned, all the data is gathered and posted immediately to Syspro.

Support for Mass

TransLution allows the item mass to be specified when configuring the product and also now supports the option to calculate the parcel mass at automatically when the parcel is completed at the end of the checking process.