Configuring Master Data

There are a range of setup options for Quality Manager that are currently done using the Master File Maintenance setup. These are the simple setup options where the user can define things like products, machines and the basic tests to perform. The screens for defining the products, tests and groups of tests that makes up a Test Method Group and for defining the expected results for each test when being performed for a specific product are defined separately using the Quality Manager Configuration forms.

The following tables that need to be configured for use with Master File Maintenance. The extract from the Master File Maintenance table is shown so that all is required is to replicate this setup on the database where Quality Manager is being implemented.

Master Files Required for Quality Manager

The data required in each of these tables is of course dependent on the environment and what products will be tested but some examples are shown below for grading wheat (as a general example).

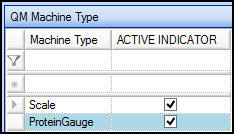

Machine Type:

This is data that is more important when tests are being performed by machines and the results will be read from the machine. It is however required to specify what type of equipment is used for doing each test. Examples would be: Scale, pH Meter, Thermometer etc. If there are a number of manual tests (determining colour or taste for example) then a machine of Manual could be used. At the moment, this data is only used for reporting and not for process validation so if required, one machine type could be used.

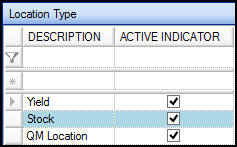

Location Type:

This field will be required if certain products can only be stored in certain locations due to hazardous material handling requirements of simply as per QC rules in the lab. If the location is not important, then a single generic location type can be created.

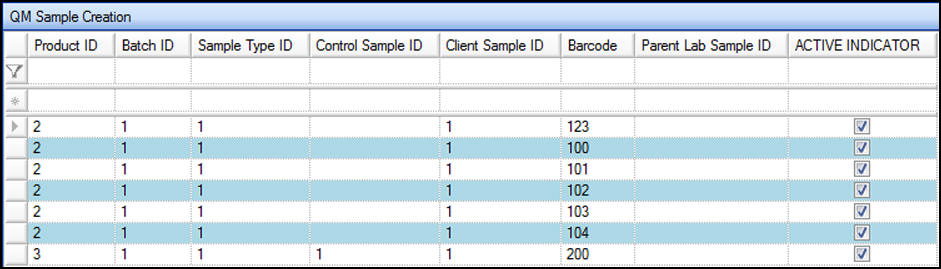

Sample:

The last option is to define a sample. This is where a sample barcode is linked to a product so that when doing tests, the system knows what Test Methods are required and what the Expected Results should be. This does not need to be done as a master file process and is probably most likely to be done as part of a barcode label printing process where when a sample is labelled, it is also added to this table for Quality Manager to know what to do when it is scanned. The only required fields as Product ID and Barcode.